Engineering Plastics

thyssenkrupp Engineered Plastics is your full-line distributor of industrial plastic shapes, specializing in engineering plastics like Acetal, Nylon, PEEK, Torlon®, UHMW, and DuPont™ Vespel® for the fabricator and OEM communities.

We've Added Some new Products!

Do you need an ultra-tough FDA compliant seal and gasket material? Take a look at Fluorosint HPV.

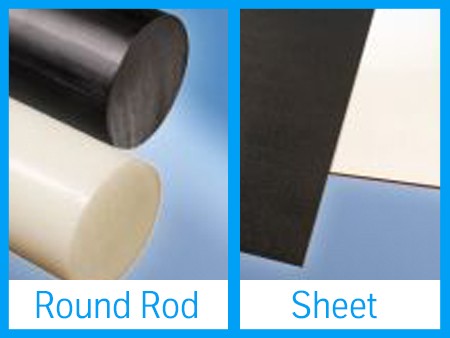

ABS (Acrylnitrile Butadiene Styrene)

ABS is an easily machined, tough, low cost rigid thermoplastic material with high impact strength, ideal for turning, drilling, milling, sawing, die-cutting, shearing. It has good chemical and stress cracking resistance to inorganic salt solutions, alkalis, acids, and some oils. ABS has excellent abrasion resistance; electrical properties, moisture and creep resistance. ABS is easily thermoformed and yields great heat detail. Extruded ABS can be easily heat formed as well. ABS comes in a variety of surface finishes and colors.

Machine Grade ABS Rod

Has a good thermal and dimensional stability and high impact strength (also at low temperature.) It is strong, shows a good scratch resistance and has a good dimensional stability. ABS can be used in temperatures ranging from -50C to +70C.

Properties:

- good mechanical strength and hardness

- resists scratching

- high surface strength

- high impact strength

- high dimensional stability

- not weather resistant

- limited resistance to acid and caustic solutions

Applications:

Parts with a high impact strength also in the cooling. Machine Grade ABS Rod is available in 17 diameters from 1/4"-6" and in 8 ft. lengths on diameters of 1/4"-2" and 4 ft. lengths on diameters of 2 1/4"-6". In colors of natural or black.

Machine Grade ABS Plate

Has a good thermal and dimensional stability and high impact strength (also at low temperature.) It is strong, shows a good scratch resistance and has a good dimensional stability. ABS can be used in temperatures ranging from -50C to +70C.

Properties:

- good mechanical strength and hardness

- resists scratching

- high surface strength

- high impact strength

- high dimensional stability

- not weather resistant

- limited resistance to acid and caustic solutions

Applications:

Parts with a high impact strength also in the cooling. ABS is available in color of natural, black, and white, in 13 thickness' from 3/8"-4" and in a variety of sheet sizes.

Acetal

For general purpose parts in wet environments

- Low moisture absorption

- High strength, stiffness

- Easy to machine

- No centerline porosity in Acetron® GP

- Many formulation options: Copolymer, Homopolymer, PTFE filled, and internally lubricated/enhanced wear grade

Acetal provides high strength and stiffness coupled with enhanced dimensional stability and ease of machining. As a semi–crystalline material, acetal is also characterized by a low coefficient of friction and good wear properties–especially in wet environments.

Because acetal absorbs minimal amounts of moisture, its physical properties remain constant in a variety of environments. Low moisture absorption results in excellent dimensional stability for close–tolerance machined parts. In high mositure or submerged applications, acetal bearings outperform nylon 4 to 1. Acetal is ideally suited for close tolerance mechanical parts and electrical insulators which require strength and stiffness. It also offers resistance to a wide range of chemicals including many solvents. Information provided by: Quadrant Engineering Plastics

Acetron GP Acetal

Acetron® GP is Quadrant's general purpose copolymer acetal and is the only porosity–free acetal product available today. Investments in process technology by Quadrant now provide the performance and machinability of acetal without center core porosity. The in-line photometric quality procedure assures every plate and rod is porosity-free making it the preferred acetal for food contact and medical applications. Acetron® GP natural and black are FDA, USDA, NSF, Canada AG and 3A-Dairy compliant.

Delrin Acetal

Delrin, a homopolymer acetal, is also manufactured and stocked in rod and plate. It offers slightly higher mechanical properties than Acetron® GP Acetal, but may contain a low–density center, especially in larger cross–sections. Acetron® GP Acetal also offers better chemical resistance than homopolymer acetal.

Delrin is better suited for small diameter, thin-walled bushings that benefit from the additional strength abd rigidity of homopolymer acetal.

Delrin AF Blend

A unique thermoplastic material for use in moving parts in which low friction and long wear life are important. It is a combination of PTFE fibers uniformly dispersed in Delrin acetal resin. This combination offers 3 times better wear characteristics than unfilled Delrin.

Delrin AF Blend, supplied as a 2:1 blend of Delrin AF100 and Delrin 150 resins, has excellent sliding/friction properties. Bearings made of Delrin AF Blend can operate at higher speeds while exhibiting reduced wear. These bearings are also essentially free of slip-stick behavior because the static and dynamic coefficient of friction are closer than with most plastics.

Delrin AF Blend retains 90% of the strength that is inherent in unmodified Delrin acetal. Some properties are changed due to the addition of the softer PTFE fiber. The natural color of Delrin AF Blend is dark brown.

Delrin AF 100

Unblended Delrin AF, offers a slightly higher limiting PV and lower coefficient of friction due to additional PTFE content. This added PTFE typically decreases the wear capability and impact strength. Delrin AF 100 is available on a custom basis.

Cast Acrylic

Cast Acrylic has unusual optical clarity, excellent light transmission and outstanding weatherability. It is unaffected by sunlight, resists aging and maintains good stability under variable conditions of heat, cold, moisture and other exposure, it will not warp, crack, craze or corrode. Cast acrylic may be preferred for some industrial and commercial applications because it is more optically perfect than molded or extruded types of acrylic products. It provides high tensile strength and good resistance to heat distortion. This is the best quality clear rod available for machining or cementing and will fabricate like wood, metal, or other plastics, with standard equipment. Half the weight of comparable glass, Cast Acrylic has good shatter resistance and excellent durability.

ECTFE

Ethylen-Chlortrifluorethylene exhibits an extraordinary impact strength at temperatures ranging from -104°F to +302°F. A great part of the product properties attributes to the very smooth surface and differentiates HALAR from other fluoropolymers. Due to the fact that E-CTFE is very pure, this material is being used to process chemicals and ultrapure water for the semiconductor industry. Also, the permeation resistance to oxygen, carbon dioxide, chlorine gas and hydrochlorid acid is 10 to 100 times better than PTFE.

Characterisitcs:

- extremely high impact strength (up to -105°F) no break on notched or unnotched IZOD impact test

- good insulation properties

- very good weather resistance

- high resistance to radiation

- very high chemical resistance

- self-extinguishing

- much more dimensional stability than PTFE

- very good sliding properties

- food safe

- high density

- limited protection against stress cracking at temperatures > 284°F

- very low moisture absorbtion at < 0.1%

Applications:

Parts which come in contact with aggressive materials (machinery building industry), lining of tanks, pumps, flanges, fittings, parts in centrifuges and control engineering industry etc...

Ertalyte®

Stability Of Acetal:

- Good for both wet and dry environments

- High strength and rigidity - ideal for close tolerance parts

- Excellent stain resistance

- Good wear resistance and excellent dimensional stability

- Better resistance to acids than nylon or acetal

information provided by: Quadrant Engineering Plastics

Ertalyte® PET-P

Ertalyte® is an unreinforced, semi-crystalline thermoplastic polyester based on polyethylene terephthalate (PET-P). It is characterized as having the best dimensional stability coupled with excellent wear resistance, a low coefficient of friction, high strength, and resistance to moderately acidic solutions. Ertalyte®'s properties make it especially suitable for the manufacture of precision mechanical parts which are capable of sustaining high loads and enduring wear conditions. Ertalyte®'s continuous service temperature is 210°F (100°C) and its melting point is almost 150°F higher than acetals. It retains significantly more of its original strength up to 180°F (85°C) than nylon or acetal.

In addition, Ertalyte® PET-P offers good chemical and abrasion resistance. Its low moisture absorption enables mechanical and electrical properties to remain virtually unaffected by moisture.

Ertalyte® is FDA compliant in natural and black. Natural Ertalyte® is also USDA, 3A–Dairy and Canada AG compliant. Ertalyte® is an excellent candidate for parts used in the food processing and equipment industries.

Ertalyte® TX

An internally lubricated thermoplastic polyester providing enhanced wear and inertness over general purpose nylon(PA) and acetal(POM) products. Containing uniformly dispersed solid lubricant, Ertalyte®TX provides a lower wear rate and coefficient of friction than unmodified polyesters like PET or PBT and even internally lubricated materials like Delrin® AF blend.

Ertalyte® TX excels under both high pressure and velocity conditions. It is also ideally suited for applications involving soft metal and plastic mating surfaces. Wear is nearly 2 times better compared to Standard Ertalyte.

Fluorosint®

The Most Dimensionally Stable PTFE-Based Product Available-

- Chemical resistance parallels PTFE

- Continuous use temperature to 500°F (260°C)

- Better wear resistance than PTFE

- Higher load carrying capacity

- 1/9 of the deformation under load

- Lower coefficient of thermal expansion

Fluorosint's unique properties are the result of a proprietary process in which synthetically manufactured mica is chemically linked to PTFE. This bonding results in properties not normally attainable in reinforced PTFE. Fluorosint® grades offer an excellent combination of low frictional properties and dimensional stability.

Competitive Material Comparison Versus Other PTFE's

| Fluorosint® | Rulon® | ||||||

|---|---|---|---|---|---|---|---|

| 207 | 500 | HPV | MT-01 | J | LR | 641 | |

| Tensile Strength (psi) | 1,500 | 1,100 | 1,450 | 2,100 | 2,000 | 2,000 | 2,000 |

| Hardness | D65 | D70 | D65 | D73* | D60 | D60 | D60 |

| CLTE (in/in/°F) | 5.7 X 10-5 | 2.5 X 10-5** | 4.9 X 10-5 | 3.0 X 10-5* | 6.8 X 10-5 | 6.2 X 10-5 | 5.7 X 10-5 |

| COF | 0.1** | 0.15 | 0.015 | 0.018 | 0.2 | 0.25 | 0.3 |

| Limiting PV (ft-lbs. in2-min) | 8,000 | 8,000 | 20,000** | 4,500 | 7,500 | 10,000 | 10,000 |

| K-Factor | 85* | 600 | 38** | 200 | 47* | 45* | |

| Deformation under load | 5.00% | 1.10%** | 3.20% | 0.20%** | 3.00% | 3.00% | 4.00% |

| FDA Compliant | Yes* | No | Yes* | No | No | No | Yes* |

Competitive Material Comparison Versus Other PTFE's

| Fluorosint® | Rulon® | ||||||

|---|---|---|---|---|---|---|---|

| 207 | 500 | HPV | MT-01 | J | LR | 641 | |

| Tensile Strength (psi) | 1,500 | 1,100 | 1,450 | 2,100 | 2,000 | 2,000 | 2,000 |

| Hardness | D65 | D70 | D65 | D73* | D60 | D60 | D60 |

| CLTE (in/in/°F) | 5.7 X 10-5 | 2.5 X 10-5** | 4.9 X 10-5 | 3.0 X 10-5* | 6.8 X 10-5 | 6.2 X 10-5 | 5.7 X 10-5 |

| COF | 0.1** | 0.15 | 0.015 | 0.018 | 0.2 | 0.25 | 0.3 |

| Limiting PV (ft-lbs. in2-min) | 8,000 | 8,000 | 20,000** | 4,500 | 7,500 | 10,000 | 10,000 |

| K-Factor | 85* | 600 | 38** | 200 | 47* | 45* | |

| Deformation under load | 5.00% | 1.10%** | 3.20% | 0.20%** | 3.00% | 3.00% | 4.00% |

| FDA Compliant | Yes* | No | Yes* | No | No | No | Yes* |

Fluorosint® HPV

When you need seal or gasket material with high load and wear resistance, and it has to be FDA compliant, look no further than Fluorosint HPV. This PTFE material is filled with a synthetic mica that is bonded to virgin PTFE. Fluorosint HPV has a unique combination of properties that include low friction and high dimensional stability.

Fluorosint® 500

Has nine times greater resistance to deformation under load than unfilled PTFE. Its coefficient of linear thermal expansion approaches the expansion rate of aluminum, and is 1/5 that of PTFE–often eliminating fit and clearance problems. It is 1/3 harder than PTFE, has better wear characteristics and maintains low frictional properties. Fluorosint® 500 is also non–abrasive to most mating materials.

Fluorosint® 207

Unmatched dimensional stability, excellent creep resistance and white color uniquely position this material to serve FDA regulated applications. It is non–permeable in steam and complies with FDA's regulations 21 CFR 175.300. Its relative wear rate is 1/20 the rate of PTFE below 300°F (150°C) making it an excellent choice for aggressive service bearings and bushings.

Hydex

Hydex 202 Opaque, Hydex 301 - Transparent Rigid Polyurethane Rod and Slab

Manufactured from Isoplast engineering thermoplastic resins which is unique in the fact that they are amorpous. The amorphous resins will yield the following properties: good impact resistance, good dimensional stability, excellent chemical resistance, and low mositure absorption. Applications: Bearings, Gears, Small engine components, Industrial hardware.

Hydex 4101 - PBT - Polybutylene Terephthalate

Polyester is not a new resin, it has been sold for over 20 years. It is widely used in all segments of the industrial community. Hydex® 4101 is made from PBT resin and is sold under a variety of trade names: Rynite® from DuPont, UltraDur® from BASF, & Valox® from GE Plastics. Hydex 4101 PBT Polyester has excellent chemical resistance making it a popular product in harsh environments. It's FDA approval makes it a good choice for the food processing industry. it is widely used in electronics because it has excellent electrical properties. Applications: Food Piston Pumps, Valve Bodies, Feeder Blocks, Timing Screws, Gears, Cams, Bushings, Bearings, Wear Strips, Valves Features: No Center Line Porosity, Low Coeffcient of Friction, Hard Durable Surface, FDA Grade - Natural White Hydex® 4101.

Hydlar

Hydlar ZF Rod and Slab Hydlar® ZF is a blend of DuPont Nylon filled with DuPont Kevlar® Aramid fibers. The Kevlar® filler changes the physical properties, but is not an abrasive as glass fillers. Kevlar® increases the tensile and flexural strength as well as increasing the impact and heat properties. Hydlar® ZF is ideal for structural and wear resistant applications. This material outperforms metals, glass, or other reinforced plastics. Applications: Pulleys Bearings-Heavy Load Casters Wear Plates High Strength Wheels & Rollers Canning Mandrels.

Ketron PEEK

Chemically Resistant Structural And Bearing And Wear Material For Continuous Use To 480°F (250°C)

- Excellent chemical resistance

- Very low moisture absorption

- Inherently good wear and abrasion resistance

- Unaffected by continuous exposure to hot water or steam

Information provided by: Quadrant Engineering Plastics

Ketron PEEK 1000

This general purpose grade is unreinforced and offers the highest elongation and toughness of all PEEK grades. The newly available black PEEK 1000 is ideal for instrument components where aesthetics are important, as well as for seal components where ductility and inertness are important.

Ketron PEEK GF30

The addition of glass fibers significantly reduces the expansion rate and increases the flexural modulus of PEEK. This grade is ideal for structural applications that require improved strength, stiffness or stability, especially at temperatures above 300°F (150°C).

Ketron HPV (Bearing Grade)

Carbon fiber reinforced with graphite and PTFE lubricants, our newest grade of PEEK offers the lowest coefficient of friction and the best machinability for all PEEK grades. An excellent combination of low friction, low wear, high Limiting PV, low mating part wear and easy machining, make it ideal for aggressive service bearings.

Ketron PEEK CA30

The addition of carbon fibers enhances the compressive strength and stiffness of PEEK, and dramatically lowers its expansion rate. It offers designers optimum wear resistance and load carrying capability in a PEEK–based product. This grade provides more thermal conductivity than unreinforced PEEK–increasing heat dissipation from bearing surfaces improving bearing life and capability.

Noryl PPO

Noryl EN265 Extruded Sheet

Noryl EN 265 is thermoformable sheet which is an excellent replacement for metals where stability, durability, U.L. approval is required. Extruded Noryl EN 265 sheet combines the following characteristics:

- 265° heat resistance under load

- High impact strength down to -40°F

- Withstands virtually all acids and bases

- Excellent hydrolytic stability, features low water absorption

- Excellent electrical properties virtually unaffected in high humidity and high temperature

- Minimal effect on mechanical properties after long time exposure to hot water or steam

- U.L. V-1

- Resistant to hydrolysis

- Vacuum formable

Noryl EN265 Sheet and Slab

- Premium performance and U.L. V-O rating at .240"

- UL temperature rated at 105°C

- Stree relieved - excellent machinability

- Outstanding electrical characteristics

- Outstanding thermal properties

- High resistance to creep

- Long term dimensional stability

- Outstanding hydrolytic stability, low water absorption.

Noryl EN265 Rod

Has the same outstanding characteristics as the Sheet & Slab.

Nylon

First Choice For All General Purpose Wear And Structural Components

- Broadcast size range availability

- Good mechanical and electrical properties

- Ideal balance of strength and toughness

- Many grade options: FDA compliant, Internally lubricated, Heat stabilized

- Cast as finished parts and near net shapes (nylon 6)

Nylon's toughness, low coefficient of friction and good abrasion resistance make it an ideal replacement for a wide variety of materials from metal to rubber. It weighs only 1/7 as much as bronze. Using nylon reduces lubrication requirements, eliminates galling, corrosion and pilferage problems, and improves wear resistance and sound dampening characteristics. Nylon has a proven record of outstanding service in a multitude of parts for such diverse fields as paper, textiles, electronics, construction, mining, metalworking, aircraft, food and material handling.

Information provided by: Quadrant Engineering Plastics

Nylon 101

Of all the unmodified nylons, Nylon 101 is the strongest, most rigid and has one of the highest melting points. It is commonly specified for screw machined electrical insulators and food contact parts. It is stocked in both natural and black. Other colors are available on a custom basis. Nylon 101 natural is FDA, USDA, NSF, and 3A-Dairy compliant.

Nylatron GS Nylon

Molybdenum disulphide (MoS2) filled nylon offering improved strength and rigidity. With a lower coefficient of linear thermal expansion than Nylon 101, Nylatron® GS parts maintain better fit and clearances, and have less tendency to seize as bearings.

30% Glass-reinforced Nylon 6/6

For applications requiring higher compressive strength and rigidity, 30% glass reinforced Nylon 6/6 is also available. It is stocked in diameters ranging from 10mm to 150mm (or .394" to 5.910" in meter lengths).

Nylatron MC 907 Nylon

Unmodified type 6 nylon offering the highest strength and hardness of the nylon 6 grades. MC 907 natural is FDA, USDA and 3A-Dairy compliant. It is off-white in color and primarily used for food contact parts.

Nylatron MC 901 Nylon

Heat stabilized nylon offering long-term thermal stability to 260°F. It is blue in color and used in a variety of bearing and structural applications such as wheels, gears, and custom parts.

Nylatron GSM Nylon

Contains finely divided particles of molybdenum disulphide (MoS2) to enhance its load bearing capabilities while maintaining the impact resistance inherent to nylon. It is the most commonly used grade for gears, sheaves, sprockets and custom parts. It is grey-black in color.

Nylatron LFG

Takes the performance of Nylatron LIG and adds FDA compliance for applications where food contact is possible. Food packaging and processing equipment users can now benefit from the wear resistance, toughness and low coefficient of friction of this nylon material.

Nylatron LIG

Combines the toughness of cast PA6 with an oil-based lubricant that is encapsulated within the nylon matrix. It increases the load bearing performance of the material when compared to unfilled nylons and reduces the coefficient of friction. It is an ideal material for industrial application in conveying and processing industries.

Nylatron GSM Blue Nylon

The first cast nylon to combine both molybdenum disulphide (MoS2) and oil for the load capacity of Nylatron GSM nylon, plus improved frictional characteristics. It excels in higher pressures, and at low speeds-up to 40 fpm. It offers 20% lower coefficient of friction, 50% greater limiting PV, and a lower "k" factor than Nylatron GSM, making it ideal for slide pads, thrust washers and trunion bearings. Nylatron GSM Blue should be considered for any oil-filled nylon application. It is dark blue in color.

Nylatron NSM Nylon

Still the best bearing and wear nylon product available today. Proprietary type 6 nylon formulation produced using Quadrant's Monocast® process. Solid lubricant additives impart self-lubricating, high pressure/velocity and superior wear resistance characteristics. Nylatron NSM was developed specifically for demanding applications where larger size parts are required. It is ideal for bearings, gears and wear pads. In wear applications, Nylatron NSM lasts up to 10 times longer than standard Type 6 nylon.

Nylatron 703XL

This ultra-high performance bearing grade of PA6 provides wear resistance near the levels of Nylatron NSM with superior load bearing capability and an industry first - a near zero level of "stick-slip." This elimination of chatter provides an extraordinary amount of control for high-precision applications.

Nylatron® WP PA

The newest innovation for cost-effective, high performance material developed specifically for wear pad grade applications.

In comparison testing Nylatron® WP PA outperformed other leading Nylon materials used for wear pads and the cost is considereably less.

Benefits of using Nylatron® WP PA Material Include:

- Lighter in weight than metal

- Reduces chatter and loss of control or stick slip

- Easy to machine and fabricate

- Withstands higher loads which can reduce need for lubrication

- Excellent wear life

- Cost saving alternative to other materials

Polycarbonate

High Impact Strength With Heat Resistance To 250°F Continuous Use (120°C) -

- Excellent impact resistance, toughness and elongation properties

- Transparent

- Good dielectric properties

- Economical thermal performance

Machine Grade Polycarbonate is a transparent amorphous thermoplastic which offers very high impact strength and high modulus of elasticity. The material has a 290°F (145°C) heat deflection temperature at 264 psi, absorbs very little mositure and resists acidic solutions. These properties, in addition to good electrical characteristics, make Machine Grade Polycarbonate stock shapes an excellent choice for electrical/electronic applications. Its strength, impact resistance and transparency also make it an ideal material for certain transparent structural applications such as sight glasses and windows.

Machine Grade Polycarbonate is stress relieved making it ideal for close tolerance machined parts. Our stock shapes are produced from polycarbonate resins which meet the requirements of ASTM D 3935.

A food grade polycarbonate that is compliant with FDA, NSF, Canada AG and USP Class VI regulations is available upon request. A glass fiber reinforced polycarbonate grade is available upon request.

Information provided by: Quadrant Engineering Plastics

Polysulfone

Hot Water And Steam Performance To 300°F (150°C)

- Broad temperature range capability

- Good thermal and electrical insulation characteristics

- Hydrolysis resistant

- Radiation stability

- Low ionic impurity

PSU 1000 Polysulfone (PSU) - is an amber semi–transparent, heat–resistant, high performance engineering thermoplastic. It offers excellent mechanical, electrical and improved chemical resistance properties relative to polycarbonate. Polysulfone's properties remain relatively consistent over a broad temperature range, from –150°F (–100°C) to 300°F (100°C).

PSU 1000 Polysulfone is hydrolysis resistant for continuous use in hot water and steam at temperatures up to 300°F. Its flame resistance in UL 94–V–0 at 1/4" thickness (6.35mm) and UL 94–V–2 at 1/8" thickness (3.175mm).

PSU 1000 Polysulfone offers high chemical resistance to acidic and salt solutions, and good resistance to detergents, hot water and steam. In addition, polysulfone has excellent radiation stability, and offers low ionic impurity levels. PSU 1000 Polysulfone often replaces polycarbonate when higher temperatures, improved chemical resistance or autoclavability is required. It is commonly used for analytical instrumentation, medical devices and semiconductor process equipment components.

Food–grade PSU 1000 Polysulfone and custom colors can be special ordered. Only food–grade PSU 1000 is FDA, NSF, 3A–Dairy and USP Class VI compliant.

Information provided by: Quadrant Engineering Plastics

Polyurethane

We offer Polyurethane, an elastomeric material with outstanding properties and wear characteristics that often outperforms conventional rubber products. Urethanes come in a variety of colors and durometers (hardness).

- Superior cut and abrasion resistance

- Ability to "self-heal"

- Excellent resistance to ozone and aging

- Resistant to many oils and solvents

- Lightweight

- Sheets - both unsupported and fabric backed

- Bars

- Rods

- Tubes

- Custom Shapes

- Custom Molded Products

- Wear pads

- Metal-forming pads

- Machinery mounts

- Cutting surfaces

- Sound dampening pads

- Chute and hopper liners

- Prototype machined parts

- Bumper pads

- Gaskets Seals

- Rollers/Roller Covers

- Sandblast curtains

Techtron

Excel In Corrosive Environments To 425°F (220°C)

- Excellent chemical resistance

- Essentially zero moisture absorption

- Machines to tight tolerances

- Excellent alternative to PEEK at lower temperatures

PPS (polyphenylene sulfide) products offer the broadest resistance to chemicals of any advanced engineering plastic. They have no known solvents below 392°F (200°C) and offer inertness to steam, strong bases, fuels and acids. Minimal moisture absorption (0.01%) and a very low coefficient of linear thermal expansion (28x10-6), combined with Quadrant's proprietary stress relieving processes, make these PPS products ideally suited for precise tolerance machined components. In addition, PPS products exhibit excellent electrical characteristics and are inherently flame retardant.

Information provided by: Quadrant Engineering Plastics

Techtron PPS

Unlike reinforced PPS products, Techtron® PPS is easily machined to close tolerances. It is ideal for structural applications in corrosive environments or as a PEEK replacement at lower temperatures. Techtron® PPS is off white in color. FDA compliant.

Techtron HPV

Techtron HPV exhibits excellent wear resistance and a low coefficient of friction. It overcomes the disadvantages of virgin PPS caused by a high coefficent of friction, and of glass fibre reinforced PPS which can cause premature wear of the counterface in moving–part applications.

- Excellent wear and frictional behavior

- Excellent chemical and hydrolysis resistance

- Very good dimensional stability

- Good electrical insulating and dielectric properties

- Inherent low flammability

- Excellent resistance against high energy radiation

- 0.01% moisture

- 33x10-6 coefficient of linear thermal expansion.

PTFE

PTFE, (polytetrafluoroethylene), provides unmatched chemical, electrical, mechanical, and thermal properties for multiple applications. PTFE is used for gasket and packaging materials in chemical processing equipment, as electrical insulation, as bearings, seals, and piston rings in mechanical applications, especially those requiring anti-stick characteristics. In addition to chemical, heat, corrosion, and impact resistance. PTFE is weather resistant, flexible, FDA/USDA compliant, non-stick, non-flammable, low dielectric constant, chemically inert, and good at low temperatures.

PTFE Sheet

Available in 15 thickness' from 1/32"-2" and sheet sizes of 12"x12", 12"x24", 12"x48", 24"x24", 24"x48", 36"x36", 48"x48". Etched PTFE sheets are available for bonding, as well as additional sheet sizes and cut to size sheets. PTFE sheet is priced per sheet.

PTFE Rectangular Bar

Available in 13 thickness' from 1/8"-2" and in widths of 1", 2", 2 1/2", 3 1/2", 4", and 5. Standard length is 12" and 48". PTFE bar is priced per foot.

PTFE Pipe

Available in four formulations: Schedule 40 FEP, Shcedule 40 PFA, Schedule 80, and Schedule 80 PFA. It's available in normal sizes of 1/8"-2".

PTFE Tubing

Available in 46 combinations from 1/8"IDx1/4"OD-3"IDx3 1/2"OD. Standard length 6ft. and price is per foot.

PTFE Tubing Metric Sizes

Available in 3 formualtions PTFE, FEP, PFA. The metric sizes are available in 11 sizes metric sizes from 1MMx3MM – 14MMx16MM and imperial sizes from .040x.118 – .551x.630. Tubing is priced per foot.

PTFE Chemical Tubing

Available in 3 formulations TFE, FEP, and PFA. PTFE TFE is for temperatures ranging up to 260°C (500°F). It resists all corrosive chemicals and its dielectric properties favor it for electronic and electrical service. PTFE FEP is manufactured from melt-extrudable resin and can be made available in long continuous lengths. Its chemical and dielectric properties are equal to TFE, however some temperature is sacrificed down to 400°F. PTFE PFA is a fluoropolymer with good melt processability and improved mechanical characteristics at elevated temperatures. TFE tubing is available in 2 formulations Industrial Wall and Heavy Wall. Industrial wall tubing is available in 19 ID's from 1/32"-1 1/2" and in the Heavy Wall from 1/16ID-7/8". The price is per foot. FEP Tubing is also available in 2 formulations – Industrial Wall and Heavy Wall. Industrial wall is available in 18 ID's from 1/32"-1 1/2" and Heavy wall is available in 18 ID's from 1/16"-2". PFA Tubing is available in the same formulations with Industrial Wall 18 ID's from1/32"-1 1/2" and Heavy Wall with 18 ID's from 1/16"-2".

PTFE Spaghetti Tubing

Available in 32 different gauges and 4 different wall types. Heavy Wall, Standard Wall, Thin Wall, and Light Wall. Heavy Wall is available in 20 sizes from ID .022-. 186, Standard Wall is available in 31 sizes from ID .012- 1.010, Thin Wall is available in 29 sizes from .010 ID-.632 ID, Light Wall is available in 28 sizes from .010 ID-.507ID. Pricing is per 100-foot length. This tubing offers abrasion, shock, and chemical resistance. The unlimited flexibility, crack resistance, high temperature and pressure resistance are just some of the properties making this tubing ideal for a variety of industrial applications.

PTFE Tape Skived

Available in 7 thickness' from .005-.060 and in standard widths of 12", 18", 24". PTFE skived tape meets requirements of MIL-P-22241a and AMS 3651. Cementable PTFE tape etched is available on request. Tape is priced per pound.

PTFE Treating Agents

Three formulations of treating agents are available; ChemGrip Treating Agent - a high flash point etching solution for treating TFE and other fluoropolymers to make their surfaces bondable using conventional adhesives available in pint, quart, and gallon containers.

PTFE Round Beading

Miniature rod is available in 18 diameters from .028-.200 and supplied in coil form, priced per 100 foot length.

PTFE Heat Shrink Tubing

Has excellent electrical properties, protective see-through shields for electronic connections, protective, jacketing for use in industries such as: aerospace, chemical, electronic, medical, nuclear, and automotive. It is available in 12 diameters from 1 1/4"-9" and in standard lengths up to 20 feet.

TFE Glass Fabric & Tapes

Heat seal tapes have a smooth PTFE coated fiberglass surface, which is an excellent release surface, designed to wear longer with a sure hold at high temperatures. Skived PTFE Tape has a silicone adhesive coating for wire wrap and insulation tape in high dielectric and high temperature applications. PTFE Coated Fiberglass is available in 4 thickness' from .003-. 010 and in widths of 37 1/2 for thickness' .003-. 006 and 38" for a .010 thickness. PTFE Coated Fiberglass with Silicone Adhesive is available in 4 thickness' from .003-. 010 in 36" widths. PTFE Coated Fiberglass with Acrylic Adhesive is available in 4 thickness' from .003-. 010 in 36" widths. Skived PTFE Tape with Silicone Adhesive is available in thickness' from .003-. 010 and in 36" widths. Premium Film Tape with Silicone Adhesive is available in .002 thickness and in an 18" width.

ChemGrip Bonding Kit

Contains sodium etchant and epoxy adhesive for on the job bonding of TFE and other fluoropolymers. Each kit can etch and bond 2-4 square feet.

ChemGrip Cement

An epoxy adhesive, which will bond treated TFE to all common materials – wood, glass, metal, and ceramics. Cement is available in pint containers.

FEP Roll Cover

Has the same properties as PTFE Tape in 19 diameters from 1/2" -12.00". The pre-shrinkage ID and post-shrinkage ID are listed in the AIN Plastics catalog for easy reference.

Radel R PPSU

Best Impact And Steam Resistance To 400°F (205°C)

- High resistant to steam autoclaving

- Impact resistant

- High modulus of elasticity and heat resistance

Radel R polyphenysulfone (PPSU) is an amorphous high performance thermoplastic offering better impact resistance and chemical resistance than polysulfone and polyetherimide (Ultem® PEI).

Radel offers superior hydrolysis resistance when compared to other amorphous thermoplastics as measured by steam autoclaving cycles to failure. In fact, Radel R has virtually unlimited steam sterilizability. This factor makes it an excellent choice for medical devices as steam autoclaves are widely used to sterlize medical devices. It also resists common acids and bases–including commercial washing solutions – over a broad temperature range.

Radel R is stocked in Natural (bone white) and available in transparent and custom colors. It is commonly used in sterilization trays, dental and surgical instrument handles, and in fuild handling coupling and fitting applications. Radel R is USP Class VI complaint.

It is suitable for use in electronic assembly equipment and devices that must withstand solder temperatures. Radel has a heat deflection temperature of 405°F (207°C). Radel is FDA compliant and NSF compliant under standards 51 and 61.

Information provided by: Quadrant Engineering Plastics

Ryton

PPS (polyphenylene sulfide) products offer the broadest resistance to chemicals of any advanced engineering plastic. They have no known solvents below 392°F (200°C) and offer inertness to steam, strong bases, fuels and acids. Minimal mositure absorption and a very low coefficient of linear thermal expansion, combined with Quadrant's proprietary stress relieving processes, make these PPS products ideally suited for precise tolerance machined components. In addition, PPS products exhibit excellent electrical characteristics and are inherently flame retardant.

40 Percent Glass Reinforced Ryton PPS

This product is the most recognized PPS. It is the compression molded analogue to Ryton R4 resin. It offers better dimensional stability and thermal performance than Techtron® PPS and maintains its strength to above 425°F (220°C).

Bearing Grade Ryton PPS

Internally lubricated and carbon fiber reinforced compression molded PPS offering a low coefficient of thermal expansion and uncompromised chemical resistance. It is well suited for and wear applications or when an electrically conductive material is require.

Semitron®

Static Dissipative Products With Thermal Capabilties To 500°F (260°C)

The Semitron® ESd family of static dissipative products was designed by Quadrant for use where electrical discharge in operation is a problem. They are commonly used for sensitive electronic components including: integrated circuits, hard disk drives and circuit boards. Semitron products are also an excellent choice for material handling applications, and components in high speed electronic printing and reproducing equipment.

Semitron® ESd products are inherently dissipative and electrically stable unlike many other "dissipative" plastic shapes. They do not rely on atmospheric phenomena to activate, nor are surface treatments used to achieve dissipation. Static electricity is dissipated through these products as readily as it is dissipated along the surface. All of these products dissipate 5KV in less than 2 seconds per Mil–B–81705C.

Information provided by: Quadrant Engineering Plastics

Semitron® ESd 225

Ideal for fixturing used in the manufacturing of hard disk drives or for handling in–process silicon wafers. It is tan in color.

- Surface resistivity: 1010–1012 Ω / sq.

- Thermal performance to 225°F (107°C)

- Good wear resistance.

Semitron® ESd 410C

Ideal for handling integrated circuits through the test handler environment. It is black in color and opaque.

- Surface resistivity: 104–106 Ω / sq.

- Thermal performance to 410°F (210°C)

- Low stress for tight tolerance machining

- High strength and stiffness.

Semitron® ESd 420

The only, truly dissipative plastic product for use in high temperature applications.

- Surface resistivity: 106–109 Ω / sq.

- Thermal performance.

Semitron® ESd 500HR Static Dissipative PTFE

Reinforced with a proprietary synthetic mica, Semitron® ESd 500HR offers an excellent combination of low frictional properties and dimensional stability. Semitron® ESd 500HR should be considered wherever PTFE is used. It is ideal for applications where controlled bleed off of static charges is critical. It is white in color.

- Surface resistivity: 1010 - 1012 ohms/sq

- Thermal performance to 500°F (260°C)

- Thermally insulative

- Very low coefficient of friction

- Broad chemical resistance

Semitron® ESd 520HR Static Dissipative PAI

Semitron® ESd 520HR has an industry first combination of electrostatic dissipation (ESd), high strength and heat resistance. This new ESd material is ideal for making nests, sockets and contactors for test equipment and other device handling components. The key features of 520HR are its unique ability to resist dielectric breakdown at high voltages (>100V). The graph below demonstrates the electrical performance of plastic materials commonly used in automated test handlers. Typical carbon fiber enhanced products become irreversibly more conductive when exposed to even moderate voltage.

Only Semitron® ESd 520HR maintains its performance throughout the voltage range, while offering the mechanical performance needed to excel in demanding applications.

- Surface resistivity: 1010 - 1012 ohms/sq

NEW! Semitron® MDS 100

Semitron® MDS 100 sets a new standard in performance for machinable polymers. This material is an excellent choice when you need a highly rigid, stable, moisture resistant platform for precision structural applications.

Product Benefits:

- Very low moisture absorption

- Machines easily to precise dimensions

- Non-fiber filled material allows for greater machining stability

- Very strong and stiff

- Low CLTE means parts stay in spec

- Available in thin cross sections

- Tensile modulus of 1,500,000 psi offers in plate thicknesses ranging from 1 mm to 10mm

Common Uses Include:

- Test Sockets for the semiconductor manufacturing industry

- Fixtures for electronics testing

- Mounting point for precision diagnostic equipment

- Positioning platforms for miniature motion control devices

NEW! - Semitron® MP 370

Semitron® MP370 is an excellent choice for test socet designers. This material is not subject to the "soft center" or inconsistent properties that can be found in injection molded shapes. Homogeneous Semitron® MP 370 is a stable platform for your design ideas.

Product Benefits:

- Very low moisture absorption

- Exceptional machinability

- Very small holes and tight hole patterns are possible

- Strength and stiffness that exceed unfilled PEEK materials

- Low internal stressess and no "soft center" problems assiciated with injection molded blanks

- Finer cleaner detail possible

- Good value, an ideal choice for specific application environments

Common Applications:

- IC Test sockets for semiconductor manufacturing equipment

- Structural parts in electronics and telecom equipment'

- Insulating blocks and fixtures in diagnostic equipment

UHMW-Tivar

UHMW-PE is ultra high molecular weight polyethylene. UHMW is lightweight and longwearing, providing excellent performance in packaging equipment. Key benefits of UHMW include abrasion and impact resistance. Additional features include: low coefficient of friction, chemically inert, self-lubricating, FDA/USDA approved, and machinable. UHMW lessens the noise of bottles, cans, and conveyor chains. Packaging lines with UHMW components run quietly. The low coefficient of friction allows it to release food particles and other substances preventing build-ups and bottle-necking. UHMW causes no undesirable taste, smell, or discoloration. This material requires no special care and can be cleaned with water, steam, detergents, or disinfectants.

TIVAR 1000

An excellent general–purpose material, TIVAR 1000 (natural) is a cost–effective solution for food handling problems, and meets FDA, USDA and 3–A Dairy guidelines for food processing and handling. Poly Hi Solidur also offers custom colors compounded with FDA/USDA approved pigments, which meet FDA and USDA guidelines for food processing and handling. Whether your business is grain, pharmaceuticals, pizza dough or frozen poultry, TIVAR material will reliably move your materials and products.

TIVAR Recycled

Utilizes a cost effective blend of resins to maintain an acceptable combination of TIVAR® properties for less demanding, non–FDA applications.

TIVAR H.O.T.

Formulated to maintain key performance properties in an extended temperature range, TIVAR® H.O.T.* will excel in a variety of industrial manufacturing environments where temperatures range up to 275°F, nearly 100° higher than competing UHMW–PE formulations. TIVAR® H.O.T. reduces the oxidization rate of the material at higher temperatures thereby slowing material degradation and extending wear–life in chemical, elevated temperature and thermo–cycling environments. In many applications, TIVAR® H.O.T. will last up to 10 times longer in higher temperature environments and has excellent wear and release characteristics.

TIVAR AntiStatic

If static electricity poses a significant problem in your manufacturing environment, take action by choosing TIVAR® AntiStatic. With a surface resistivity range of 105 to 109 (ohms/cm2) TIVAR® AntiStatic handles tough conditions where dust and static electricity can cause problems.

TIVAR DrySlide

Modified with special dry lubricants, TIVAR® DrySlide has the lowest coefficient of friction of any of the TIVAR® products.

TIVAR Ceram P

For high load, high speed and severe sliding abrasion applications, TIVAR® Ceram P® should be THE material of choice. Its high tensile strength and wear resistance have been successful in the lumber, paper, steel and agricultural industries. Composed of virgin polymer and premium additives, TIVAR® Ceram P® is a shatter–resistant alternative to sintered ceramics, reducing parts wear and machine maintenance downtime.

TIVAR Oil Filled

This advanced product uses oil filled polymers to lubricate mating surfaces with a dynamic coefficient friction formula of less than 0.14. With TIVAR Oil Filled, conveyors operate more effectively, without the effort and added expense of unnecessary lubrication. On TIVAR Oil Filled guides, sprockets and conveyor components, chains move easily with less tension, stretching or binding.

TIVAR UV Resistant

Outdoor applications for TIVAR® UV Resistant are endless. The modified formula retains all the key properties of TIVAR® – low friction surface, wear and corrosion resistance, impact strength – and, exhibits enhanced stability for outdoor, UV–exposed applications.

TIVAR CleanStat

Can cut downtime and fines build–up in a variety of applications. It eliminates static build–up problems, meets FDA and USDA guidelines for food contact and exhibits a longer wearing, lower coefficient of friction sliding surface than stainless steel.

Duratron® PAI (Torlon PAI)

Stiffness And Strength At Temperature Extremes

- Maintains strength and stiffness to 500°F (260°C)

- Minimal expansion rate to 500°F (260°C)

- Excellent wear resistance in bearing grades

- Able to endure harsh thermal, chemical and stress conditions

Duratron® PAI will be referred to as Torlon PAI below

With its versatile performance capabilities and proven use in a broad range of applications, Torlon polyamide-imide (PAI) shapes are offered in extruded and compression molded grades.

Torlon is the highest performing, melt processable plastic. It has superior resistance to elevated temperatures. It is capable of performing under severe stress conditions at continuous temperatures to 500°F (260°C). Parts machined from Torlon stock shapes provide greater compressive strength and higher impact resistance than most advanced engineering plastics.

Torlon PAI's extremely low coefficient of linear thermal expansion and high creep resistance deliver excellent dimensional stability over its entire service range. Torlon is an amorphous material with a Tg (glass transition temperature) of 537°F (280°C). Torlon stock shapes are post-cured. This eliminates the need for additional curing by the end user in most situations. A post-curing cycle is sometimes recommended for components fabricated from extruded shapes where optimization of chemical resistance and/or wear performance is required.

For large shapes or custom geometries like tubular bar, compression molded Torlon shapes offer designers the greatest economy and flexibility. Another benefit of selecting a compression molded grade is that resins are cured, or "imidized" prior to molding which eliminates the need to post-cure shapes or parts fabricated from compression molded shapes.

Information provided by: Quadrant Engineering Plastics

Torlon 4203 Electrical Grade

Exhibits superior electrical insulation at elevated temperature and is primarily designed for structural electrical and electronic applications. In addition, Torlon 4203 displays excellent resistance to radiation.

Torlon 4301 Bearing Grade

Retaining the same physical and chemical properties as 4203, Torlon 4301 is designed for bearing and wear applications, such as non-lubricating bearings, seals, valve and compressor parts, piston parts, and bearing cages. It is used where high strength, resistance to elevated temperatures, and solvent resistance is an important application requirement.

Torlon 4503

This grade is compression molded & commonly used for dies and patterns of formed metal parts or as thermal insulators and isolators. It is similar in composition to Torlon 4203 PAI, and selected when larger shapes are required.

Torlon 4501

PAI is compression molded & well suited for general purpose wear and friction parts. It has a higher compressive strength and can therefore carry more load than Torlon 4540. It is similar in composition to Torlon 4301 PAI, and selected when larger shapes are required.

Torlon 5530

30% glass–reinforced & compression molded. It is ideal for higher load structural or electronic applications. This grade is similar in composition to Torlon 5030 PAI. It is selected for larger shapes or when the greatest degree of dimensional control is required.

Request a Quote or Information

Fill out the form below this and a representative from thyssenkrupp Engineered Plastics will reach out to you soon.