MoldMAX Copper Products

Description

MoldMAX HH (High Hard) is the premier copper mold alloy. This alloy has a hardness and strength comparable with standard tool steels but its thermal conductivity is four to six times higher.

Typical Uses

MoldMAX HH is used for injection mold cores, cavities, and blow mold pinch-offs.

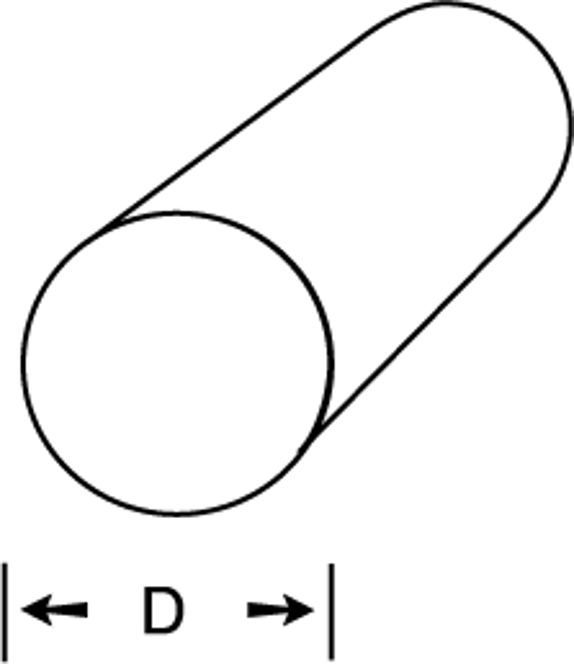

Round Bar

| Diameter | Purchase Small Quantities | Quote From Copper and Brass Sales |

|---|---|---|

| 0.5 - 6.0 | Buy From Online Metals Now | See Quote Form Below |

Round Bar

| Diameter | Purchase Small Quantities | Quote From Copper and Brass Sales |

|---|---|---|

| 0.5 - 6.0 | Buy From Online Metals Now | See Quote Form Below |

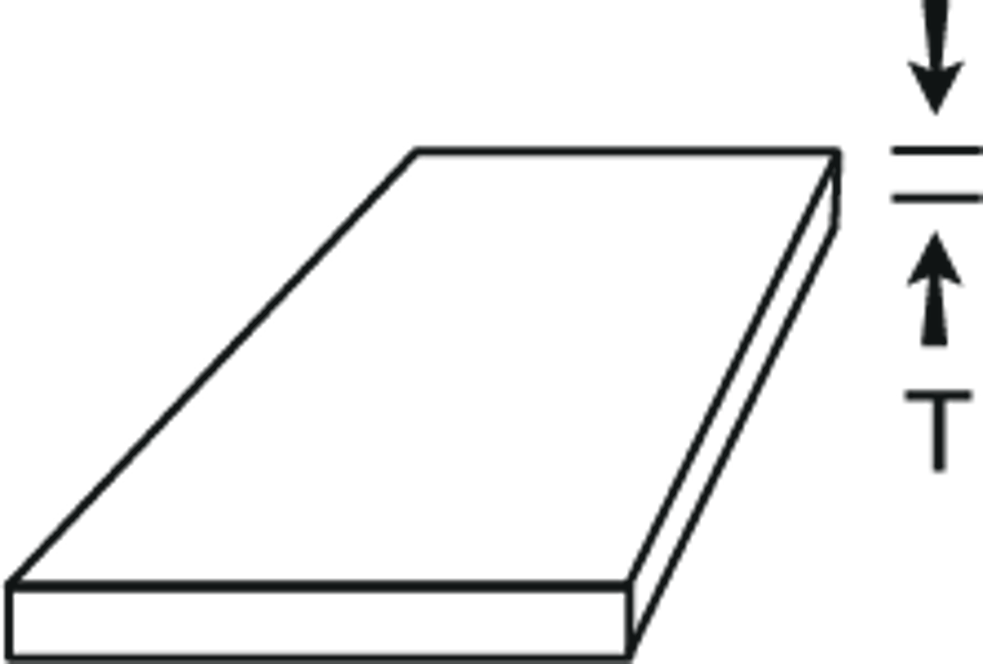

Plate

| Thickness | Quote From Copper and Brass Sales |

|---|---|

| 0.25 - 8.0 | See Quote Form Below |

Plate

| Thickness | Quote From Copper and Brass Sales |

|---|---|

| 0.25 - 8.0 | See Quote Form Below |

Additional dimensions in this grade may be available upon request. Contact us for more information.

Description

MoldMAX LH (Low Hard) is the premier copper mold alloy. This alloy has a hardness and strength comparable with standard tool steels but its thermal conductivity is four to six times higher.

Typical Uses

MoldMAX LH is used for injection mold cores, cavities, and blow mold pinch-offs.

Plate

| Thickness | Quote From Copper and Brass Sales |

|---|---|

| 0.25 - 6.0 | See Quote Form Below |

Plate

| Thickness | Quote From Copper and Brass Sales |

|---|---|

| 0.25 - 6.0 | See Quote Form Below |

Additional dimensions in this grade may be available upon request. Contact us for more information.

Description

Copper mold alloy with high strength and good thermal conductivity. Contains no beryllium. Hardness comparable to standard tool steels.

Typical Uses

Injection mold cores and cavities.

Plate

| Thickness | Quote From Copper and Brass Sales |

|---|---|

| 2.0 - 12.0 | See Quote Form Below |

Plate

| Thickness | Quote From Copper and Brass Sales |

|---|---|

| 2.0 - 12.0 | See Quote Form Below |

Additional dimensions in this grade may be available upon request. Contact us for more information.

Description

Copper nickel silicon chromium alloy with high conductivity and above average strength.

Typical Uses

Injection mold cores, cavities, and pinch-offs.

Round Bar

| Diameter | Quote From Copper and Brass Sales |

|---|---|

| 0.5 - 4.0 | See Quote Form Below |

Round Bar

| Diameter | Quote From Copper and Brass Sales |

|---|---|

| 0.5 - 4.0 | See Quote Form Below |

Plate

| Thickness | Quote From Copper and Brass Sales |

|---|---|

| 1.0 - 4.0 | See Quote Form Below |

Plate

| Thickness | Quote From Copper and Brass Sales |

|---|---|

| 1.0 - 4.0 | See Quote Form Below |

Additional dimensions in this grade may be available upon request. Contact us for more information.

Description

Beryllium copper mold alloy with high conductivity.

Typical Uses

Used in applications that require high thermal conductivity along with normal strength and wear demands.

Round Bar

| Diameter | Quote From Copper and Brass Sales |

|---|---|

| 0.5 - 4.0 | See Quote Form Below |

Round Bar

| Diameter | Quote From Copper and Brass Sales |

|---|---|

| 0.5 - 4.0 | See Quote Form Below |

Plate

| Thickness | Quote From Copper and Brass Sales |

|---|---|

| 1.0 - 3.5 | See Quote Form Below |

Plate

| Thickness | Quote From Copper and Brass Sales |

|---|---|

| 1.0 - 3.5 | See Quote Form Below |

Additional dimensions in this grade may be available upon request. Contact us for more information.

MoldMAX Properties

English Units

English Units

| Product | Rockwell Hardness HRC | Thermal Conductivity BT/ft-hr-F | Charpy V-Notch Impact Strength Ft-lb | Yield Strength (ksi) | Tensile Strength (ksi) | Thermal Expansion Cofficient 10-6 / F |

|---|---|---|---|---|---|---|

| MoldMAX HH | 40 | 75 | 4 | 145 | 170 | 9.7 |

| MoldMAX LH | 30 | 90 | 12 | 110 | 140 | 9.7 |

| MoldMAX XL | 30 | 40 | 15 | 105 | 115 | 9.3 |

| MoldMAX V | 28 | 92 | 4 | 105 | 125 | 9.7 |

| MoldMAX SC | 20 | 145 | 40 | 90 | 105 | 9.8 |

MoldMAX Properties

English Units

English Units

| Product | Rockwell Hardness HRC | Thermal Conductivity BT/ft-hr-F | Charpy V-Notch Impact Strength Ft-lb | Yield Strength (ksi) | Tensile Strength (ksi) | Thermal Expansion Cofficient 10-6 / F |

|---|---|---|---|---|---|---|

| MoldMAX HH | 40 | 75 | 4 | 145 | 170 | 9.7 |

| MoldMAX LH | 30 | 90 | 12 | 110 | 140 | 9.7 |

| MoldMAX XL | 30 | 40 | 15 | 105 | 115 | 9.3 |

| MoldMAX V | 28 | 92 | 4 | 105 | 125 | 9.7 |

| MoldMAX SC | 20 | 145 | 40 | 90 | 105 | 9.8 |

Metric Units

| Product | Rockwell Hardness HBW | Thermal Conductivity W/m-C | Charpy V-Notch Impact Strength J | Yield Strength MPa | Tensile Strength MPa | Thermal Expansion Cofficient 10-6 / C |

|---|---|---|---|---|---|---|

| MoldMAX HH | 370 | 130 | 5 | 1000 | 1175 | 17.5 |

| MoldMAX LH | 285 | 155 | 16 | 760 | 965 | 17.5 |

| MoldMAX XL | 285 | 70 | 20 | 725 | 795 | 16.7 |

| MoldMAX V | 270 | 160 | 5 | 725 | 860 | 17.5 |

| MoldMAX SC | 225 | 160 | 5 | 725 | 860 | 17.5 |

Metric Units

| Product | Rockwell Hardness HBW | Thermal Conductivity W/m-C | Charpy V-Notch Impact Strength J | Yield Strength MPa | Tensile Strength MPa | Thermal Expansion Cofficient 10-6 / C |

|---|---|---|---|---|---|---|

| MoldMAX HH | 370 | 130 | 5 | 1000 | 1175 | 17.5 |

| MoldMAX LH | 285 | 155 | 16 | 760 | 965 | 17.5 |

| MoldMAX XL | 285 | 70 | 20 | 725 | 795 | 16.7 |

| MoldMAX V | 270 | 160 | 5 | 725 | 860 | 17.5 |

| MoldMAX SC | 225 | 160 | 5 | 725 | 860 | 17.5 |

Request a Quote

Fill out the form below and a representative from Copper and Brass Sales will reach out to you soon.